Gimmick-free technology that is always advancing and always learning.

Gimmick-free technology that is always advancing and always learning.

Step 1 : Molecular Design

Select mode of molecular assembly

Required degree and type of cure-functionality for chemical and physical properties and co-polymerisation dynamics

Functional side groups for compatibility and adhesion

Component blocks for desired physical properties

End groups for synthesis reactivity and/or product characteristics such as adhesion and compatibility

Step 2 : Synthesis

Small scale laboratory synthesis

Initial reaction profile and progress including inter-step evaluation fo reaction progress

Preliminary reactivity test of candidate oligomer

Preliminary evaluation of physical and rheological properties

Drop-in candidate molecule into test formulation for screening test

Move to small batch pilot synthesis of molecules that show desired potential and performance

Step 3 : Molecular Characterisation

Stability during synthesis

Post-synthesis stability under variable temperature conditions

Colour and colour stability

Viscosity and Molecular weight distribution

Refractive index

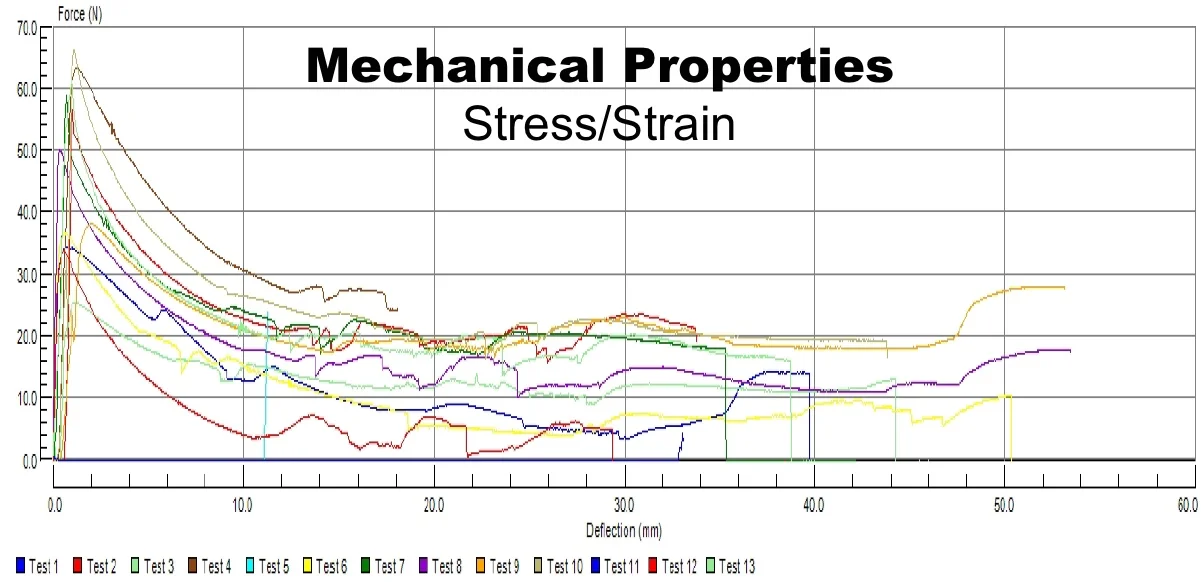

Mechanical Properties; including Tensile Strength, Elongation, Flexural strength and displacement, Elastic and Plastic deformation and Yield Stress.

Secondary Mechanical properties such as Scratch Resistance, Marring Resistance, Impact resistance

Chemical properties such as Glass-Point transition, water absorption, chemical and solvent resistance, stain resistance

Colour and performance stability under accelerated Ultra-Violet ageing